Brazing alloys for soldering and brazing of various metals

Silver alloys with different silver content and copper-phosphorous can be widely applicable in installing of all kinds of industry as well as home refrigeration and air conditioning equipment, electronics and different constructions.

Soldering alloys are low-temperature, free-flowing filler metals for joining similar and dissimilar metals (i.e.copper to steel). The joints are safe, cadmium-free.

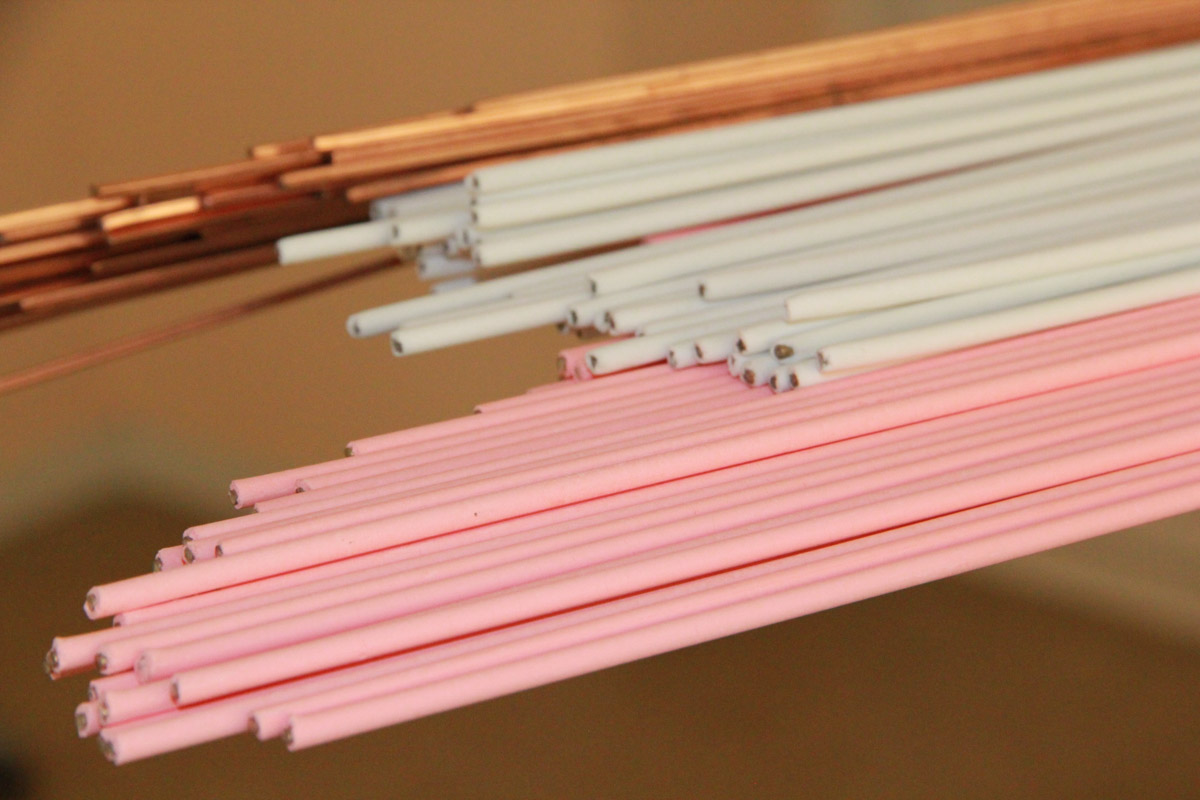

Flux coated silver alloy 40%

-

Form: round rods 2x500 mm

Chemical composition:Ag 40%-Cu 30%-Zn 28%-Sn 2%

Melting range: 650°-710° C

Working temperature: 690°C

Recommended for brazing steel, copper, copper alloys and nickel alloys. Not recommended for aluminium and magnesium.

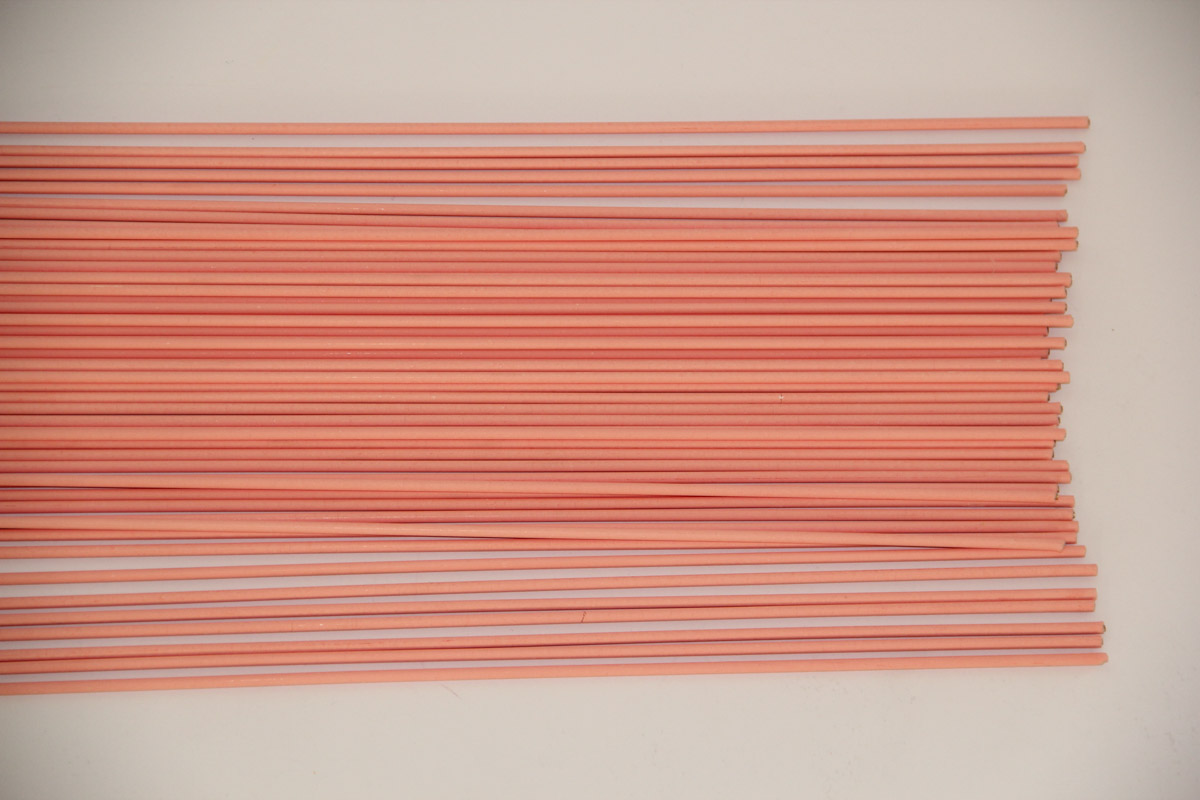

Flux coated silver alloy 30% Ag

Form:round rods 2x500 mm

Chemical composition:Ag 30%-Cu 36%-Zn 32%-Sn 2%

Chemical composition of flux: Boric acid 20-30%-Potassium bifluoride 20-30%-Potassium tetrafluoroborate 10-20%

Melting range:665°-755°C

Working temperature:740°C

Particulalry suitable for massive brass welding with low capillarity.

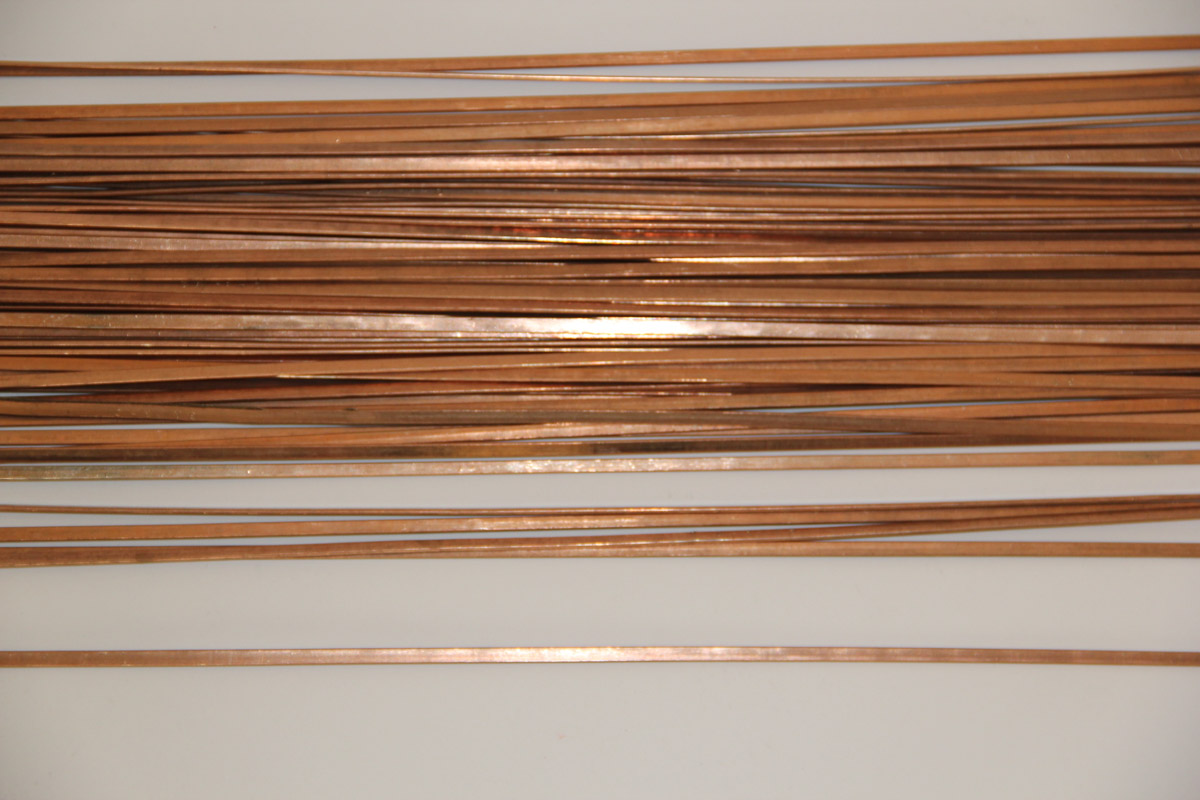

Cooper-phosphorous alloy with 5% of silver without flux

-

Form: square rods 2x2x500 mm

Chemical composition:Ag 5%-Cu 89%-P 6%

Melting range: 645°-815°C

Working temperature: 710°C

Has been developed primarily for use in copper, however, its application hasbeen extended to other non-ferrous copper alloys.

This alloy is commonly used in refrigeration, air conditioning, electrical conductors, pipes for hot and cold water and pre-fabricated houses.

Its a copper-phosphorus alloy with intermediate percentage of silver with good flow properties, ductility and self-fluxing in copper. It is not advisable its use in nickel alloys and iron-based alloys, under penalty of having formation of brittle compounds at the interface of the joint, giving less good properties. Similary, it is not advisable to use this alloy in sulfurous environments.

Silver alloys with different composition of 0%, 2%, 15% of silver without flux. For different soldering and brazing.

REFCO Brazing torch with Piezo igniting head for Propane or MAP gas cylinder

Anti-flare system: Brazing torch can be used at any angle without igniting the liquidPressure adjustment function: Flame can be adjusted to suit various applicatonsSafety locking system: Equipment with lock lever to prevent accidents and misuse by children or unfamiliar workerRemovable flame diffuser: Covers the pipe and increases the heat around the tube to keep the welding time short. Acts also as a shield to prevent the fire from damaging other thingsGas consumption 168 g/hFuel Propane (16847,9881693) or MAP Pro Gas (16867, 4661261) |

MAP PRO gas cylinder for higher temperature, net weight 400 g

RECTORSHIELD™

THERMAL ABSORBTION COMPOUND

-

Heat absorption paste for use on copper and other types of metal pipe to help prevent damage to sensitive controls, valves, plastic faucet parts, equipment, and other soldered connections.

It greatly reduces heat transfer by absorbing thermal energy from the heat and flames during soldering, brazing or welding.